THE IMPORTANCE OF WORKSITE DUST CONTROL

For individuals working in the construction and demolition industries, silica dust is one of the most deadly risks.

When grinding, cutting, drilling, or polishing materials containing silica, inhalation of silica dust (also known as crystalline silica) is a significant risk. Brick, concrete, cement, stone, drywall, grout, mortar, and tile are examples of common building materials.

Because silica dust is so minute (approximately 100 times smaller than sand), it is easily inhaled and lodges deep in the lungs. Silicosis, a respiratory condition that damages the lungs and makes breathing difficult, can be caused by inhaling silica dust on a regular basis.

You and your team can safely operate without worrying about acquiring health problems as a result of being exposed to dangerous dust if you have suitable dust control systems in place. The best defence is eliminating dust at the source and never letting it into the air. Grinders, mixers, jackhammers, tile cutters, and drills should all have a practical suction casing or shroud to confine the dust and gather it by an effective vacuum system.

To keep yourself or your employees safe from silica dust, make sure you take the essential precautions on the job.

Using industrial vacuums to remove this debris on site is one of the most excellent strategies to reduce silica dust inhalation. An industrial vacuum can gather silica dust and other hazardous particles before they become airborne, removing them at the source.

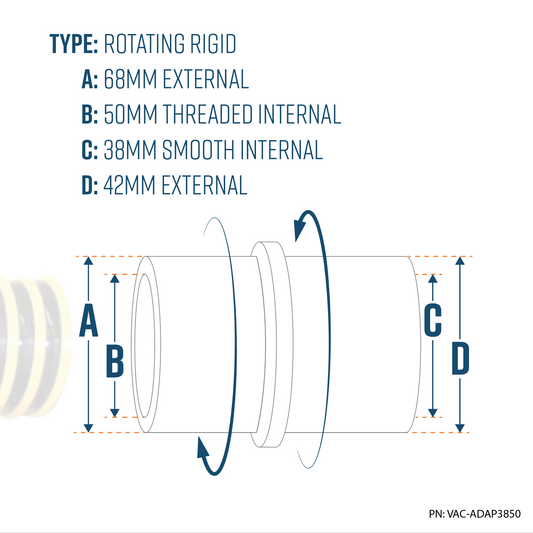

Many machinery and tools come with suction attachments to which you may connect your industrial vacuum to extract dust while working on various materials. The better you regulate dust and extract it as soon as possible, the safer your job site will be.

Vacuums or dust extractors are used to improve the work environment and eradicate hazardous particles in the air. This puts a lot of responsiblity on the dust extractor's ability to separate fine dust. The dust extractor is classed in accordance with a standardised test to ensure that it meets the requirements indicated in the applicable work environment laws. There is a complete description of how the vacuum tests are performed, and there are three classification levels with tests in line with IEC 60335.2.69 for each class to validate the machine unit's and filter elements' efficiency.

Controlling dust at your workplace can be difficult, especially if you don't have the correct tools or skills. Our team of knowlesgeable experts can help you with determining your finest dust control solutions if you're seeking for the right dust control solution for your work.

We provide a large selection of dust management tools and equipment to assist you to keep your job site as clean and dust-free as possible. Don't hesitate to contact us to see how we can help you.

Store Locator

Store Locator Login

Login

Cart

Cart