C2 Tint 457ml Bottle Espresso

C2 Tint 457ml Bottle Espresso (mixes with 5L fresh water)

SKU:C2TC-Es

Order by 2pm for Same Day Dispatch

Order by 2pm for Same Day Dispatch

Couldn't load pickup availability

Product Information

C2 Tint transforms dull gray concrete into decorative, low-maintenance finished concrete flooring. This non-flammable, water-reducible formulation penetrates and colors cementitious surfaces without risk of etching the surface or corroding nearby architectural metals. Use C2 Tint alone or in layers over gray, integrally colored, acid-stained or color hardened concrete for an unlimited range of colors. Apply penetrating C2 Tint to concrete before hardening/densifying with C2 Super Hard or C2 Hard, and then apply the appropriate Crete Colors protective treatment to seal and enhance the color with a high-gloss protective finish. Concentrated C2 Tint minimizes freight, handling, storage and container disposal costs.

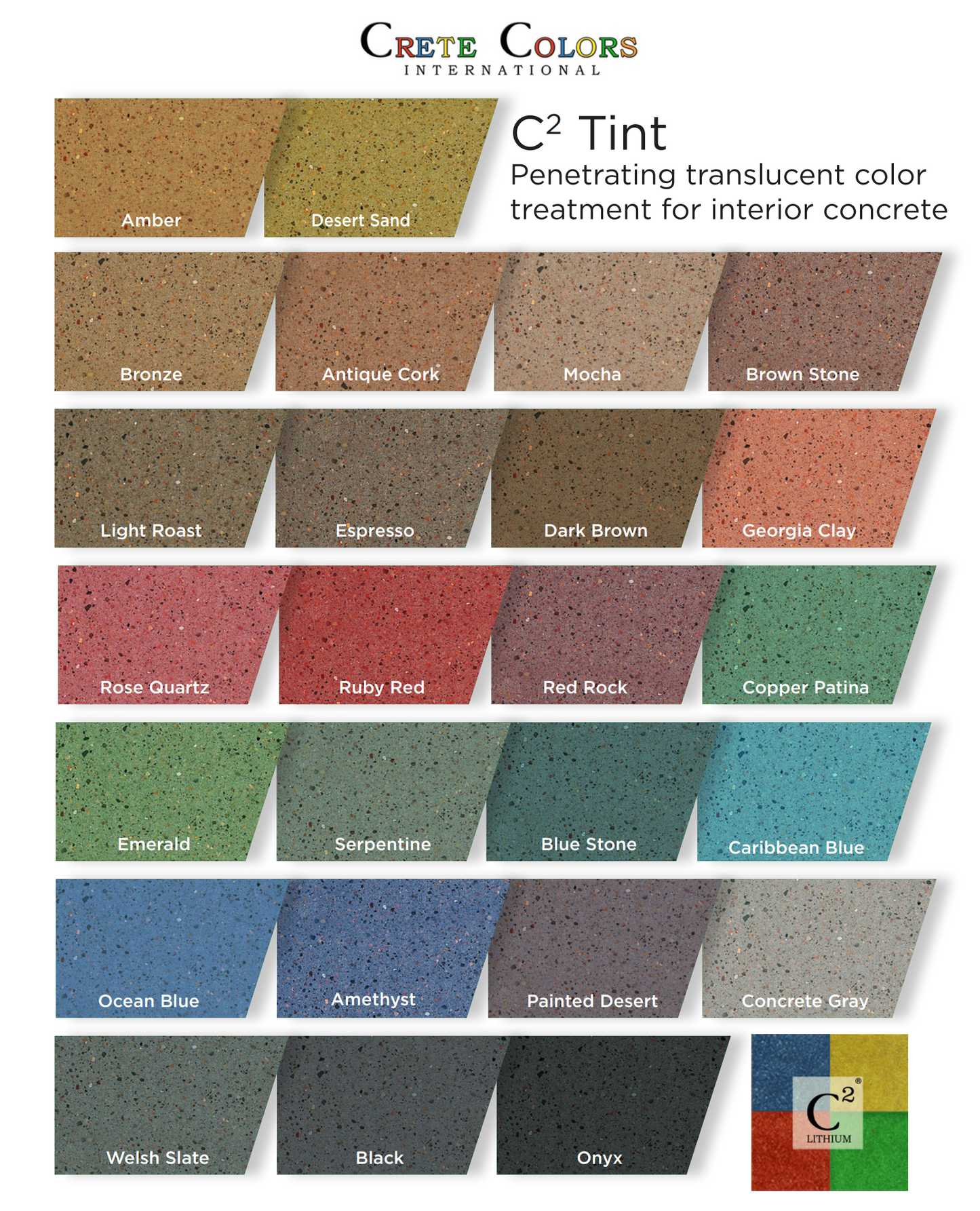

Note. C2 Crete Colors International Colour Chart for C2 TINT OPTIONS.- A proprietary, non-flammable, water-reducible formulation, which penetrates and colors concrete surfaces.

- Does not etch the concrete or corrode adjacent architectural metals.

- Adds color & depth to diamond-polished concrete.

- Available in many colors that may be used alone or in layers to produce an unlimited range of color shades

ADVANTAGES

- Adds color & depth to diamond-polished concrete.

- Enhances integrally colored, acid stained, color hardened or concrete colored with solvent based dyes.

- Ideal for use under C2 lithium-silicate hardeners/densifiers.

- VOC Compliant. Non-flammable. Non-toxic. Non-corrosive. Low odor. Suitable for use in occupied spaces.

- Contains no harmful acids. Will not etch polished concrete surfaces or corrode surrounding metals. No need to neutralize.

- Easy application and fast drying lets color be added and blended.

- Produces consistent gem-like color on any age concrete floor.

- Penetrates deeper than acid stains or conventional color pigments. Will not peel or flake.

- Standard colors may be intermixed to create an unlimited number of color variations.

- Additional coats may be applied to improve color depth, uniformity and intensity.

Limitations

- C2 Tint is translucent. Variations in the concrete before staining will still be noticeable after staining.

- Not intended for exterior applications or surfaces exposed to intense ultraviolet light.

- Not for use on surfaces exposed to standing water

Preparation

Protect people, vehicles, property and nearby surfaces not to be treated from contact with the product or over spray.

Over spray and spills may be difficult or impossible to remove. Use plastic sheeting or other proven protective material, fastened with blue painters tape or other tape that will not leave adhesive residues.

The concrete surface must be clean and dry. Contaminants may prevent penetration of the stain. Remove all curing compounds, dirt, dust and other contaminants with the appropriate Crete Colors surface preparation cleaner.

After cleaning, spray clean water lightly to confirm the surface wets uniformly. If it does not, more surface preparation is needed.

Freshly placed concrete must be at least 21 days old before coloring. Once concrete is placed, protect the surface from all construction activities before staining. Do not store building materials on newly placed concrete surfaces. Avoid standing water.

Surface & Air Temperatures

For best results keep air flow and surface temperatures consistent during application. Surface and air temperatures should be 10-32°C (50-90°F).

Equipment

Apply using a clean, low-pressure sprayer, microfiber pads, brush, roller or rags. Wear "spiked" shoes when walking in wet C2 Tint.

Storage & Handling

Apply product within 24 hours of dilution.

Published shelf life assumes storage of unopened containers in a cool, dry place. Maintain temperature of 10-32°C (50-90°F). Keep from freezing. Do not crush or tear. Dispose of unused product and container in accordance with local regulations.

Regulatory Compliance

VOC Compliance, C2 Tint is compliant with the US Environmental Protection Agency's AIM VOC regulations. Contact us at sales@cretecolors.com for compliance questions with individual country regulations.

Packaging ~475ml Bottle

Dilution & Mixing

- C2 Tint is designed for dilution with fresh water. Apply product within 24 hours of dilution.

- Mix one pre-measured bottle with 5 liters of fresh water to make ready-to-use C2 Tint.

- To reduce color intensity, dilute prepared C2 Tint with up to 2 parts fresh water.

- When desirable, C2 Tint may be diluted with acetone to produce a ready-to-use stain. Use appropriate ventilation, safety equipment and job site controls when diluting with acetone.

- Blend C2 Tint colors for an unlimited range of colors.

Typical Coverage Rates

Variations in concrete quality, porosity, job site conditions, temperature and relative humidity will affect coverage rates and drying times. Calculate the target coverage rate by testing a representative section of the prepared surface using the published application instructions.

Estimated Coverage Rates

Coverage rate varies with concrete quality and porosity.

First Application:

9.18 m2 /L

400-800 ft2 / US gal

Additional Applications:

12.24 m2 /L

500-1000 ft2 / US gal

Best Practices

Before applying color, use a light water spray to confirm surfaces wet uniformly. If surface does not wet uniformly, additional surface preparation may be needed.

Harden unpolished/polished concrete with C2 Super Hard or C2 Hard after staining. Concrete must be sealed with an appropriate C2 protective treatment.

Wet or dry grind before applying C2 Tint. Dry grind or dry polish only after applying C2 Tint. Thoroughly neutralize and rinse acidstained concrete before applying C2 Tint. Mask neighboring surfaces as needed to control color bleeding. For best results, spread evenly using a microfiber pad.

When desirable, C2 Tint may be diluted with acetone to produce a ready-to-use stain. Use appropriate ventilation, safety equipment and job-site controls when diluting with acetone. When spraying, maintain consistent flow rate and spray pattern. Two thin applications of C2 Tint achieve better color intensity than one heavy coat. When diamond polishing, apply second coat of stain immediately before final dry polishing step. Thoroughly rinse equipment with fresh water between colors and after final application.

We add a custom and artistic aspect to concrete finishing, whether through color or extraordinary sheen. These solutions differ from traditional coatings because they penetrate the surface, becoming and integrated part of the concrete. Enhancing the floor with the C² colors is affordable and differentiates each project.

Shop the range of C2 Concrete Densifiers used alongside the application of Tint and Colour online. Click the below links to see other products in this range:

- Burnishing and buffing pads

- Concrete densifiers and hardeners

- Concrete sealers and protection products

- Grout and repair compounds

- Chapin Dripless Sprayers

- Microfibre Application Pads and Accessories

- Polished concrete cleaning and maintenance products

Call the team at All Preparation Equipment to discuss your project requirements further, 1800 422 992

Store Locator

Store Locator Login

Login

Cart

Cart